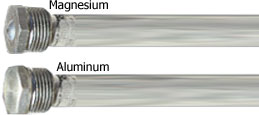

Water Heater Anode Rod: Aluminum VS Magnesium

Before diving into the details of anode rods, it’s important to note that they are only found in tank-based water heaters. Tankless water heaters do not have anode rods. Tank-based water heaters are normally under a lot of pressure from the heat they produce and the acid that is contained in water. This makes them highly susceptible to corrosion.

An anode rod is one of the first components that start to corrode. It helps to prevent rusting by delivering electrons into the water. This process is called electrolysis. The anode rod sacrifices itself to increase the lifespan of your water heater. A similar process occurs when a less reactive metal (more noble) and a more reactive metal (less noble) are put in the same conditions.

An anode rod is one of the first components that start to corrode. It helps to prevent rusting by delivering electrons into the water. This process is called electrolysis. The anode rod sacrifices itself to increase the lifespan of your water heater. A similar process occurs when a less reactive metal (more noble) and a more reactive metal (less noble) are put in the same conditions.

Anode rods are made from more reactive metals. Such metals include magnesium, aluminum, and zinc. Due to corrosion, anode rods must be replaced after every 3 to 5 years. The time it takes for them to completely wear out depends on the speed of corrosion. Several variables come to play in speeding up the rate of corrosion.

When the aluminum or magnesium anode rod has completely rusted, it will have no more electrons to give. This will stop the electrolysis process and divert corrosion to the inside of the water heater. A water heater that’s full of rust will slowly start to fail. You’ll end up paying a lot of money to get it fixed. In some cases, you may be forced to get a new water heater. It’s important to check the condition of your anode rod regularly after the first 3 years. Consult your manufacturer or user manual to determine when your anode rod needs a change. It’s important to remember that home warranties do not cover water heaters that have undergone corrosion as a result of lack of proper maintenance.

Aluminum anode rod

Features

Aluminum anode rods are built from aluminum. They react slowest with water elements and are less expensive compared to magnesium anode rods. They produce low voltage during electrolysis to slow down corrosion. The speed at which corrosion occurs depends on the condition of the water. Most tank-based water heaters include aluminum anode rods as standard equipment.

Aluminum anode rods are built from aluminum. They react slowest with water elements and are less expensive compared to magnesium anode rods. They produce low voltage during electrolysis to slow down corrosion. The speed at which corrosion occurs depends on the condition of the water. Most tank-based water heaters include aluminum anode rods as standard equipment.

For limited spaces, manufacturers include flexible aluminum rods that are designed to fit where straight anode rods can’t. They are placed directly into water heaters that are placed in low ceilings, attics, basements, beneath the stairwell, and closets. To fix the anode rod, bend its flexible sections as you slowly put it into the water heater from the top opening. Ensure that the anode rode isn’t in contact with any inner parts of the water heater.

Aluminum anode rods are a great option where the water contains a lot of sulfates. They work better at changing sulfates into hydrogen sulfides. Magnesium anode rods are known to increase the level of hydrogen sulfides to extreme levels. This creates a rotten-egg smell in the water that can be rather unpleasant.

Strong Sides

- Aluminum rods normally include an alloy of zinc and aluminum metals. This increases durability.

- They are less expensive.

- Have a longer lifespan compared to magnesium anode rods.

- They are effective in eliminating pungent smells that arise when water gets into contact with metals.

Weak Sides

- The corrosive material produced from the reaction with water can fall off and find its way into your taps and water. This may cause plumbing issues.

- Being less reactive than magnesium, aluminum reacts slowly with water elements. This means that it may not do a good job at preventing corrosion entirely.

- Aluminum produces byproducts that are a thousand times larger than its volume. These are normally deposited at the bottom of the tank in the form of jelly, contributing to sediment buildup.

- Some byproducts occasionally rise to the top of the water heater, forming a sticky substance that can clog water filters and tap aerators.

- Aluminum rods expand with time as they corrode. This makes it impossible to remove them after long periods of use due to their increased diameter.

- Rods are known to disconnect from the core wire. They fall off to the bottom of the heater and stop participating in the corrosion process after a while. This turns them into junk. Sometimes, an aluminum rod may also split into two when being removed.

- A buildup of aluminum sediments at the bottom of the heater causes noise. Users have reported hearing their water heaters operate in the middle of the night.

Aluminum deposits are harmful to the liver, kidney, brain, and spleen.

Magnesium anode rod

Features

Magnesium anode rods help to protect the inside of water heater tanks from corroding. They do this by diverting corrosion to themselves. Like their aluminum counterparts, they are also known as sacrificial rods. They are commonly used in areas that receive softer water and tend to last for a shorter period compared to Aluminum/Zinc/Tin anode rods. This is because they are more reactive and produce a higher voltage. Despite them wearing out faster than other sacrificial anodes, they provide several health benefits when dissolved in water.

Magnesium anode rods help to protect the inside of water heater tanks from corroding. They do this by diverting corrosion to themselves. Like their aluminum counterparts, they are also known as sacrificial rods. They are commonly used in areas that receive softer water and tend to last for a shorter period compared to Aluminum/Zinc/Tin anode rods. This is because they are more reactive and produce a higher voltage. Despite them wearing out faster than other sacrificial anodes, they provide several health benefits when dissolved in water.

They are a great option for in-line installations in cold water and screw-in application. Water that has high pH can produce scale inside water tanks and make the water highly alkaline. Magnesium rods provide a great alternative in such cases. Also, they are a very helpful option where the water contains high levels of chloramines and chlorine.

Strong Sides

- Magnesium anode rods provide better protection from corrosion.

- Unlike aluminum anode rods, dissolved magnesium offers health benefits.

Weak Sides

- Magnesium rods are more expensive.

- Reaction with water elements can sometimes lead to production of hydrogen sulfide which comes out as a rotten-egg smell in the water.

Overview and Conclusion

Aluminum anode rods are cheaper than magnesium anode rods. They are a good option if you live in an area that receives hard water. Unfortunately, they aren’t very safe to use and come with a host of problems. For this reason, magnesium anode rods offer a better option.

Explained neatly.

I needed a new anode rod for my Atwood water heater and started doing research. I came across this information that I thought was very helpfull. I ordered a magnesium rod, need I say more!

Thanks for the info!!

i just installed a new hot water heater and evidently it has a magnesium anode rod because the hot water side is emitting a strong rotten egg smell. Research indicates this is the formation of hydrogen sulfide due to sulfates in the water reacting with the magnesium rod. The smell is pretty bad. It’s bad enough to where I’m trying to decide on pulling it and installing an aluminum or zinc anode rod without voiding the warranty.

The best advice I got was checking the anode every 3 years. I have a customer who bought a new water heater and it only lasted 8 years where the perforation was at the top inlet and outlet. I pulled out the anode rod and it was only 6″ long with the thickness of a 20d nail. I replaced it and added two Di-electric Unions, with a magnesium rod. I’ll be back to recheck this animal, because all of my heaters last way beyond the warranty in the city but out in the county, they deteriorate so fast, we all have to fight this electrolysis mess. Thanks.